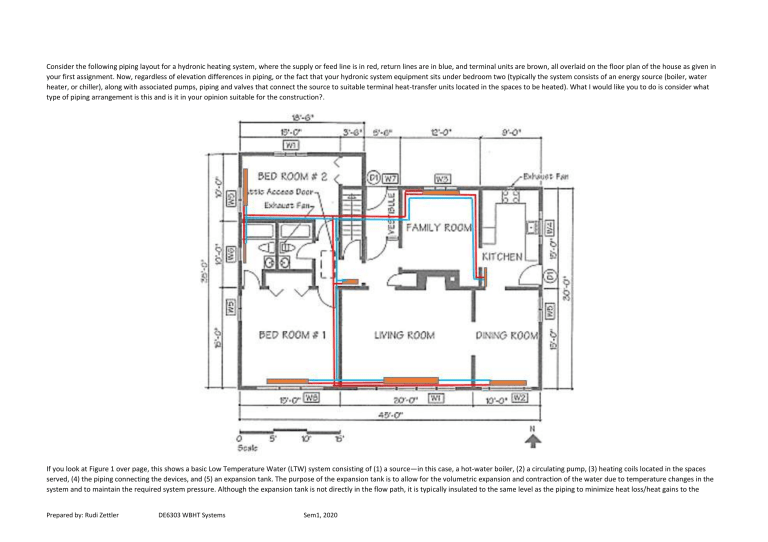

40 reverse return piping diagram

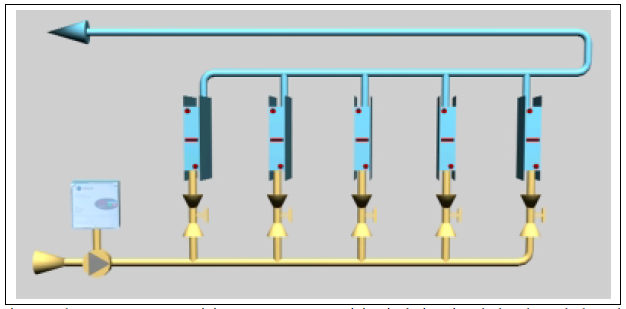

Each unit will have its own boiler and reverse return piping. 1st FL is one unit and will have 8 Pensotti wall panel radiators installed. Piping will be copper with 3/4" mains with 1/2' inch branches. 2nd FL will have 2 units (500 sqft per unit), each with its own boiler and pipping and standard cast iron radiators will be installed. Reverse Return Piping Diagram Geothermal Complete Wiring. Click Images to Large View Reverse Return Piping Diagram Geothermal Complete Wiring. You Will Go With One Pipe Monoflo Setting Or Two Pipe. Click Images to Large View You Will Go With One Pipe Monoflo Setting Or Two Pipe.

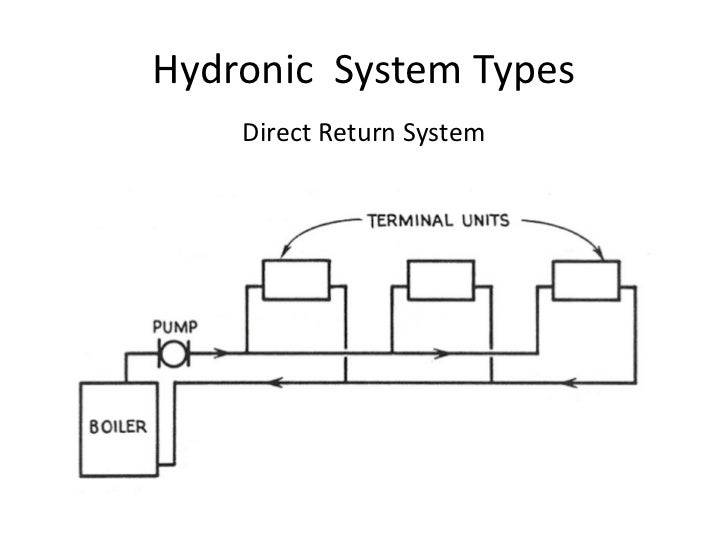

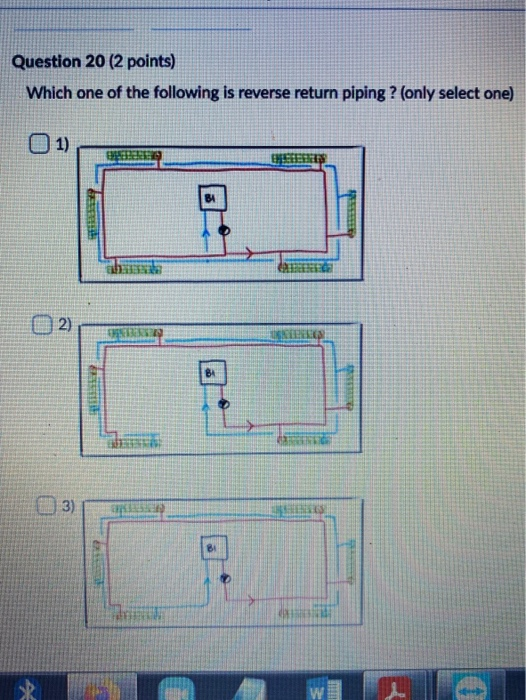

Closed-loop systems can be further classified as direct return or reverse return. Direct Return. The direct return system allows piping to be run in the most direct path to optimize piping costs. The disadvantage is that the flow at each fan coil unit or air handler usually needs to be balanced using a balancing valve.

Reverse return piping diagram

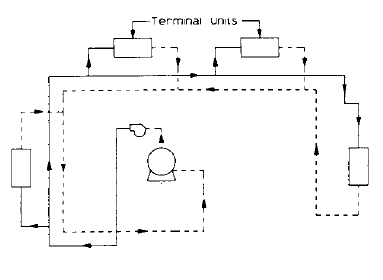

chilled water hydronic system , ahu have two type of pipe arrangement1- direct return2-reverse return reverse return keep differential pressure on control v... Apr 02, 2020 · What is Reverse return piping diagram? A reverse return system means that supplies and returns are the same length throughout the water system, making for a more even water flow to all terminals. However, unless the system is designed to be self-balancing, balancing valves will still be necessary to ensure consistent water flow. 9. Multiple boilers and storage tanks shall be installed with reverse return piping (as shown). 10. Mixing valves are recommended on all tanks if hot water temperature is above 119oF. 11. Expansion tank must be rated for use with potable water. 12. Use either indirect/tank sensor or system/pipe sensor mounted on common return to the boiler. 13.

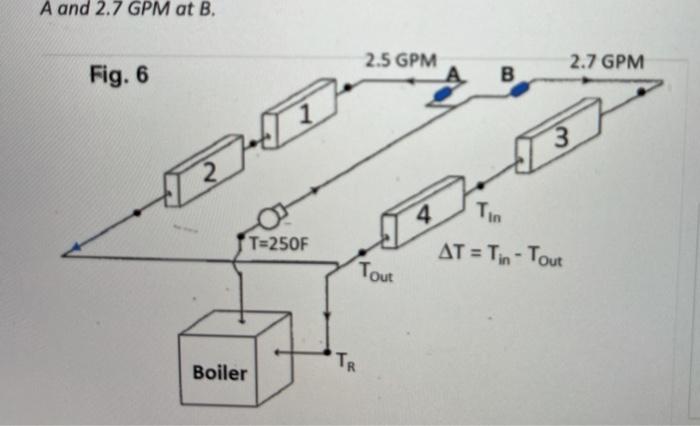

Reverse return piping diagram. In the simplest hydronic distribution system, all heat emitters are connected into a common loop, or “circuit,” with the heat source. In this arrangement, the water temperature gets progressively lower as it moves from one heat emitter to the next. This decreasing temperature must be accounted for when the heat emitters are selected and sized. A common error is to size the heat emitters based on the average water temperature in the system. With a series circuit, you must size the heat emitters based on water temperature at their specific locations within the piping circuit. If you don’t, you’ll hear complaints about overheated rooms near the beginning of a piping circuit (nearest the heat source) and uncomfortably cool rooms near the end. The main advantage of series circuits is the simple and low-cost installation. However, since water flows through all heat emitters whenever the circulator is operating, you can’t use a valve to regulate the heat output of a given heat emitter. If... Direct Return (First In/First Out) Advantages Shorter Pipe Runs Lower first cost Lower pump head Disadvantages zPoor Comfort • Does not insure adequate flow to all terminal units zNot Self Balancing • Balance valves and balancing required Reverse Return (First In/Last Out) Advantages Improved Comfort Greater assurance of In many hydronic systems, there’s a need to divide the overall system flow into equal streams that pass through several identical components. The physics necessary for this are simple: If the flow resistance of each piping path from a common source point to a common return point is the same, the flow will divide equally. Reverse return piping was developed to help achieve this goal. Dec 17, 2018 · A reverse return system is a type of closed loop system where the return header is connected to the most hydraulically remote load, as shown in Image 1. Compared to the direct return system in Image 2 where the return header is connected to the load closest to the pump, the reverse return system distributes the flows and pressures more evenly across the system, making it inherently balanced.

• piping should conform to local codes. • ball valves are shown for servicing boiler. however, local codes shall govern their usage. • pipe relief valve to open drain. three boilers reverse return db-720 thru db-1810 9. Multiple boilers and storage tanks shall be installed with reverse return piping (as shown). 10. Mixing valves are recommended on all tanks if hot water temperature is above 119oF. 11. Expansion tank must be rated for use with potable water. 12. Use either indirect/tank sensor or system/pipe sensor mounted on common return to the boiler. 13. Apr 02, 2020 · What is Reverse return piping diagram? A reverse return system means that supplies and returns are the same length throughout the water system, making for a more even water flow to all terminals. However, unless the system is designed to be self-balancing, balancing valves will still be necessary to ensure consistent water flow. chilled water hydronic system , ahu have two type of pipe arrangement1- direct return2-reverse return reverse return keep differential pressure on control v...

0 Response to "40 reverse return piping diagram"

Post a Comment