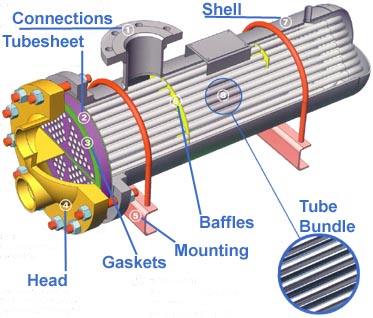

38 shell and tube heat exchanger diagram

Shell-and-Tube Heat Exchanger: Pick the Right Side Generally avoid a shell-and-tube exchanger for any service with a high risk of solidification or freezing. However, if you must use such an exchanger, I suggest putting the fluid with a risk of solidification in Shell-and-tube heat exchangers are widely used throughout the chemical industry. This paper… PDF Microsoft Word - E1-MNL032A - Design and Rating of Shell and Tube... Shell and tube heat exchangers are used extensively throughout the process industry and as such a basic understanding of their design, construction and performance is important to the practising engineer. Selection of heat transfer models and fouling coefficients for shell side and tube side.

Optimize Thermal & Mechanical Design for Shell & Tube Heat... Shell and Tube Heat Exchanger Design Software for Educational Applications*. Heat Exchangers COMPACT HEAT EXCHANGERS PART 1: Designing Plate-and-Frame Heat Exchangers Christopher Haslego, Alfa Laval Graham Polley, Use these design charts for preliminary.

Shell and tube heat exchanger diagram

Construction Basics of Shell and Tube Heat Exchangers Tubes. Heat exchangers with shell diameters of 10 to more than 100" typically are manufactured to the standards set forth by the Tubular Exchangers Manufacturers Association. Generally, the 0.625 to 1.5" tubing used in TEMA-sized exchangers is made from low carbon steel, copper, Admiralty... Shell and Tube Exchangers - an overview | ScienceDirect Topics The shell and tube exchanger accomplishes its cooling task by circulating a hot liquid around tubes which contain a cooler liquid. Shell and tube exchangers have several different configurations with different types of heads and shells; these parts are inspected and repaired in similar ways. RMP Lecture Notes | Shell and Tube Heat Exchangers: Calculations In shell and tube exchangers, the flow pattern is a mixture of cocurrent, countercurrent, and crossflow, so the LMTD does not directly apply. Tube side heat transfer coefficients are easy to determine, since the Seider-Tate equation (or equivalent) applies.

Shell and tube heat exchanger diagram. Shell and Tube Heat Exchanger Stock Vector - Illustration of chemical... Elevated heat exchanger. Heat exchangers in a refinery. Oil platform heavy gas compressor machinery detail. Norway. Vector. Uv protection cream tube with sun glasses starfish and shell on a sand beach. Tube of the watering pot shell, vintage illustration. PDF 3.1 Problem Description: Design of shell and tube heat exchanger... In present day shell and tube heat exchanger is the most common type heat exchanger widely use in oil refinery and other large chemical process, because it The objective of the project is design of shell and tube heat exchanger with helical baffle and study the flow and temperature field inside the shell... › pfd-symbols181 Process Flow Diagram (PFD) Symbols for ... - Vista Projects Process Flow Diagram equipment symbols include centrifuges and heat exchangers. Centrifuges The more dense molecules move to the outside of the centrifuge and the less dense molecules move towards the centre. Shell & Tube Heat Exchanger | Manualzz User manual | Shell & Tube Heat Exchanger. Shell and Tube Heat Exchangers Shell and Tube Heat Exchangers THE RYCROFT RANGE OF NON-STORAGE HEATING CALORIFIERS HAVE BEEN DESIGNED TO MEET THE REQUIREMENTS OF TODAY'S ENVIRONMENT AND ARE...

Shell and tube heat exchanger design 3. Shell & Tube Heat Exchangers q Shell & tube type heat exchangers are built of tubes (round or rectangular in general) mounted in shells 5. Shell Types q TEMA (the Tubular Exchangers Manufacturers Association) publishes standards defining how shell and tube exchangers should be... Figure 8. Shell and tube exchanger. Indirect contact heat exchangers keep the fluids exchanging heat separate by the use of tubes or plates etc.. A Shell and Tube Exchanger consists of a number of tubes mounted inside a cylindrical shell. Figure 8 illustrates a typical unit that may be found in a petrochemical plant. Shell and Tube Heat Exchangers Both plate type and shell and tube heat exchangers are normally used on ships. Both type of heat exchangers have advantages and disadvantages. Selection of Shell & Tube Heat Exchangers | TEMA Types... On the NEN heat exchanger, the shell and the head is welded to the tubesheet. Typically, a cover plate design is provided to facilitate tube cleaning. This TEMA category, especially the NEN, is the lowest cost TEMA design per square foot of heat transfer surface.

How to Model a Shell and Tube Heat Exchanger | COMSOL Blog Shell and tube heat exchangers are one of the most widely used type of heat exchanger in the processing industries (65% of the market according to H. S. Lee's book, Thermal Design) and are commonly found in oil refineries, nuclear power plants, and other large-scale chemical processes. PDF Thermal Design of Shell and Tube Heat Exchanger Using Elliptical... Shell and tube Heat Exchangers (STHEx) are the equipment which gives the flow of thermal energy between two or more fluids at different temperatures [1]. STHEx are used in huge industrial applications e.g. power plants, process industries, petro chemical industries, waste heat recovery etc. Shell and Tube Heat Exchangers - Basic Calculations | PDF | Calorie Heat exchangers are devices that regulate efficient heat transfer from one fluid to another. There are two main types of heat exchangers. Example 3: Taking the shell and tube heat exchanger described in Example 1, how many tubes of 3 inch diameter and 10 ft length should be used? Modelling of shell and tube heat exchangers Simulations. Shell and tube heat exchanger. Delaware vs. Modified Delaware. Varying heat transfer coefficient. For a shell and tube heat exchanger the advantages of simulations are clear. The product is expensive and technical to construct.

PDF (ii) 1‐4 exchanger (one‐shell pass and four‐ tube passes) • In most shell and tube exchangers the flow will be a mixture of co-current, counter-current and cross flow. • The usual practice in the design of shell and tube exchangers is to estimate the "true temperature difference" from the logarithmic mean temperature by applying a correction factor to allow...

PDF Design Optimization of a Shell and Tube Heat Exchanger Heat exchanger is a device used to transfer heat between two or more fluids. Of the various types of heat exchangers used in various industries, the shell and tube heat exchanger is probably the most versatile and widely used in most industrial sectors. This project captures the optimization of the total...

Shell and Tube Heat Exchangers Construction Details Shell and Tube Heat Exchanger Construction Details including shell tubes baffles tie rods spacers pass partition plates tube passes. The shell-and-tube heat exchanger is named for its two major components - round tubes mounted inside a cylindrical shell.

en.wikipedia.org › wiki › Shell_and_tube_heat_exchangerShell and tube heat exchanger - Wikipedia A shell and tube heat exchanger is a class of heat exchanger designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this type of heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it ...

Design Considerations for Shell and Tube Heat Exchangers These diagrams should accompany your basic (input-output) diagram of the heat exchanger. For example, condensation in the shell has different exponents than condensation in the tubes. Use this fundamental equation if you must, but you should consult a good resource for accurate equations.

Shell, Tube & Plate Type Heat Exchanger for Marine Diesel Engine Shell and tube heat exchangers for engine cooling water and lubricating oil cooling have traditionally been circulated with sea water. The sea water is in contact with the inside of the tubes, tube plates and water boxes. A two-pass flow is shown in the diagram but straight flow is common in small coolers.

Heat Transfer Equipment - processdesign | Shell-and-Tube Traditionally shell-and-tube heat exchangers in chemical industry. Standards and codes by TEMA (Tubular Exchanger Manufacturers Association) and ASME (American Society of Mechanical Engineers). Heat exchangers are widely seen across various types of industry...

How Shell and Tube Heat Exchangers Work (Engineering) - YouTube Learn how a shell and tube heat exchanger works! Learn about its main parts, components, how it works, design features, advantages and disadvantages.

Centrifugal Pump Maintenance - EnggCyclopedia Shell & tube heat exchanger pressure drop. But at the same time, the shell side fluid has to overcome the additional obstacles in the form of the tube bundle. Following diagram is the structure of a TEMA style shell and tube heat exchanger. The diagram itself is based on the...

Two Pass Shell and Tube Heat Exchanger Explained - saVRee Learn about the Two Pass Shell and Tube Heat Exchanger! How it works, its components, design, advantages, disadvantages and applications.

(PDF) Design and Development of Shell and Tube Heat Exchanger... Shell-and-tube heat exchangers are the most widely used. heat exchangers in process industries because of their. Design of a Heat Exchanger for a Supercritical CO2 Turbine System Kehinde Adenuga This research aims at designing a shell and tube heat exchanger which will drive a turbine...

Shell and tube heat exchangers for engine cooling Shell-and-tube heat exchanger is fabricated from round tubes that are settled in, and run parallel to a shell. Heat is transferred between the fluids by passing The sea water is in contact with the inside of the tubes, tube plates and water boxes. A two-pass flow is shown in the diagram but straight flow is...

PDF Optimal Shell and Tube Heat In designing shell and tube heat exchangers, to calculate the heat exchange area, some methods were proposed in the literature. A few number of papers present shell and tube heat exchanger design including overall heat transfer coefficient calculations (Polley et al., 1990, Polley and Panjeh...

RMP Lecture Notes | Shell and Tube Heat Exchangers: Calculations In shell and tube exchangers, the flow pattern is a mixture of cocurrent, countercurrent, and crossflow, so the LMTD does not directly apply. Tube side heat transfer coefficients are easy to determine, since the Seider-Tate equation (or equivalent) applies.

Shell and Tube Exchangers - an overview | ScienceDirect Topics The shell and tube exchanger accomplishes its cooling task by circulating a hot liquid around tubes which contain a cooler liquid. Shell and tube exchangers have several different configurations with different types of heads and shells; these parts are inspected and repaired in similar ways.

Construction Basics of Shell and Tube Heat Exchangers Tubes. Heat exchangers with shell diameters of 10 to more than 100" typically are manufactured to the standards set forth by the Tubular Exchangers Manufacturers Association. Generally, the 0.625 to 1.5" tubing used in TEMA-sized exchangers is made from low carbon steel, copper, Admiralty...

0 Response to "38 shell and tube heat exchanger diagram"

Post a Comment