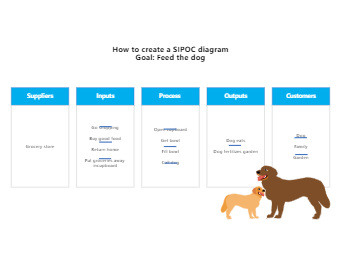

38 how to create a sipoc diagram

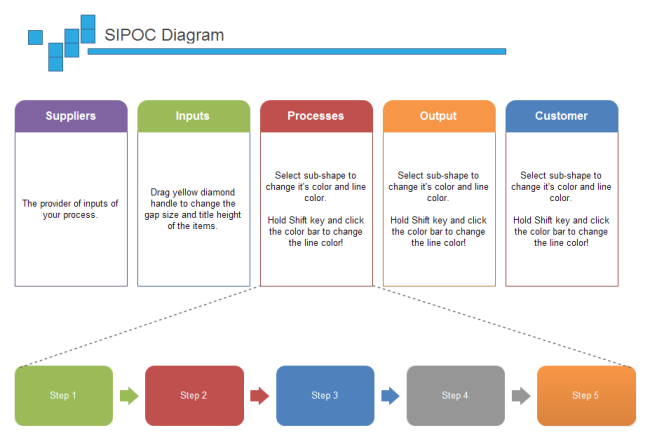

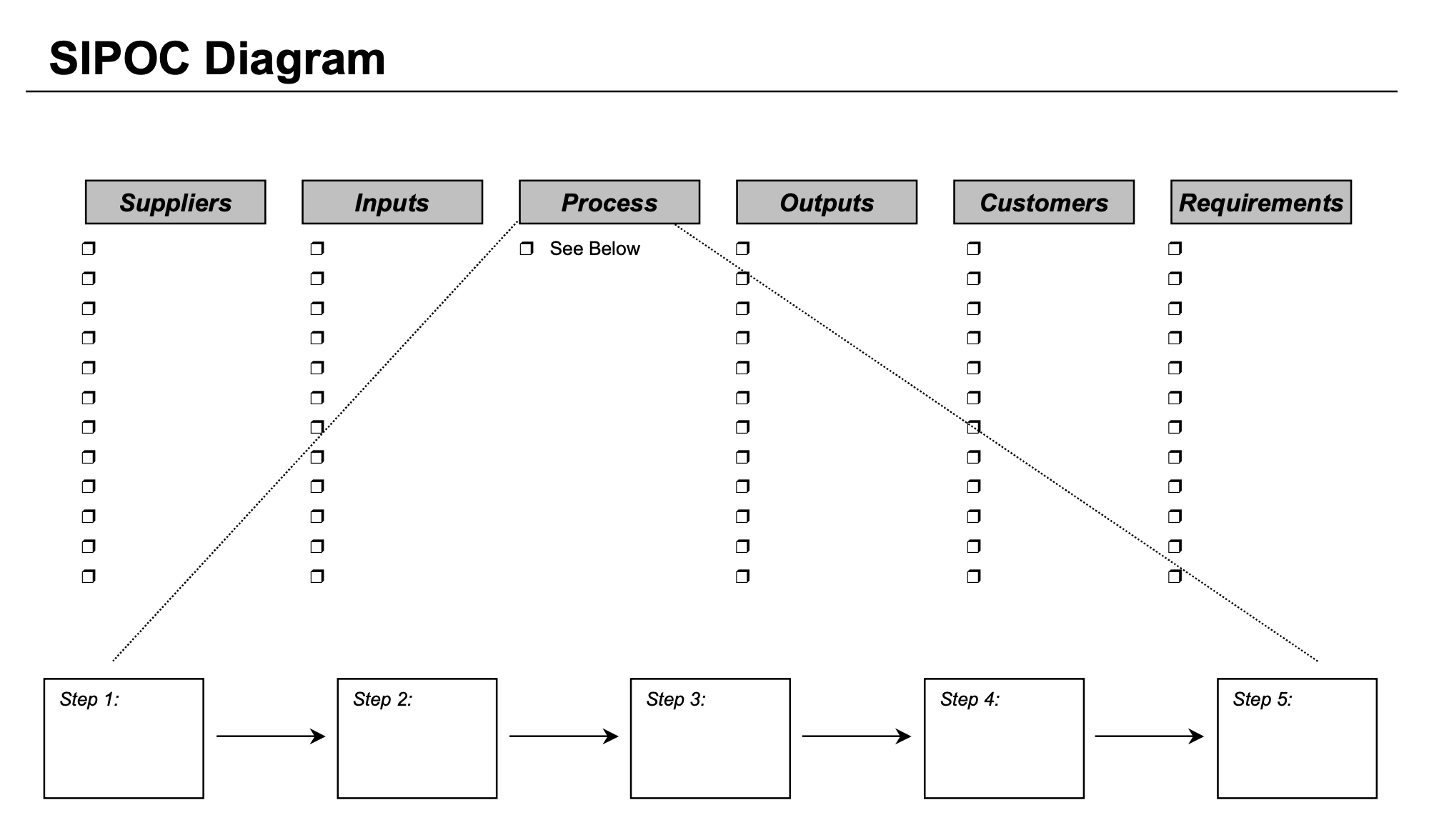

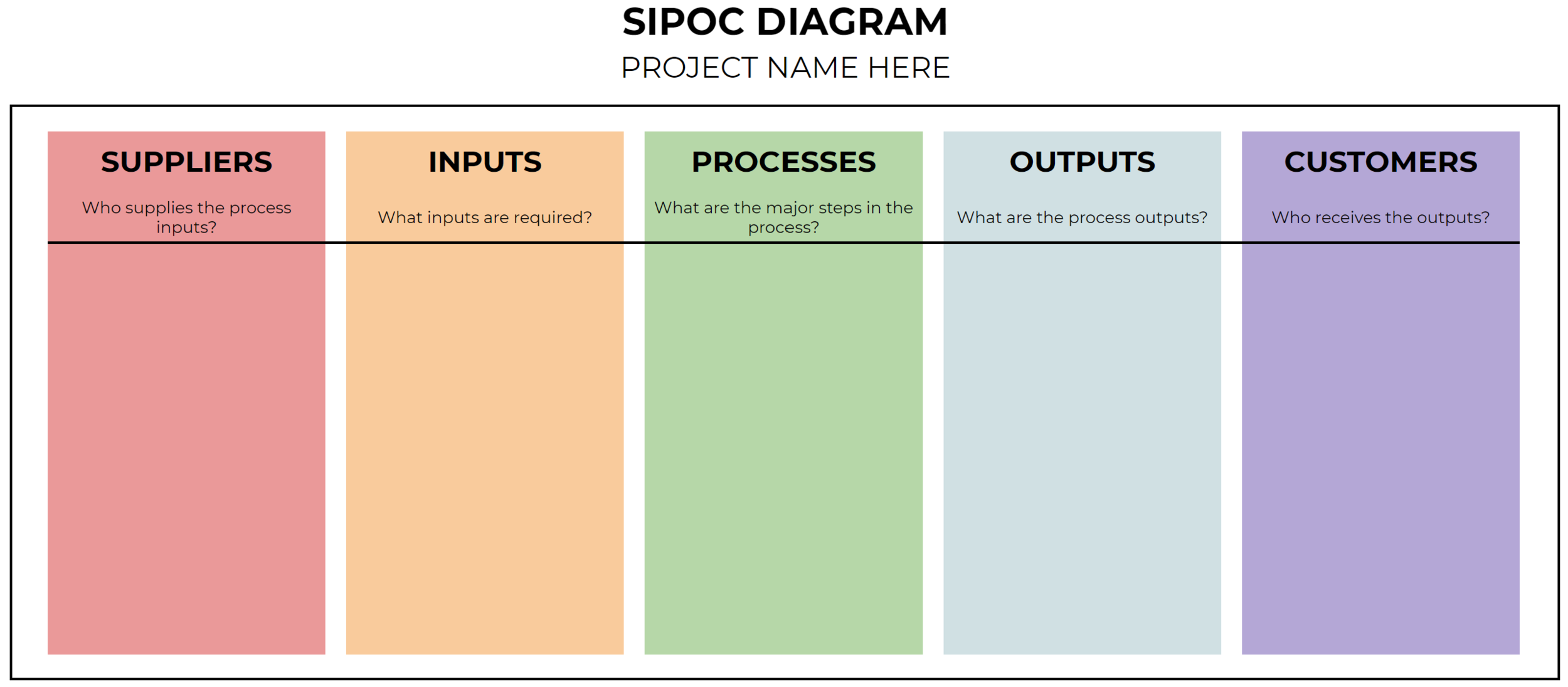

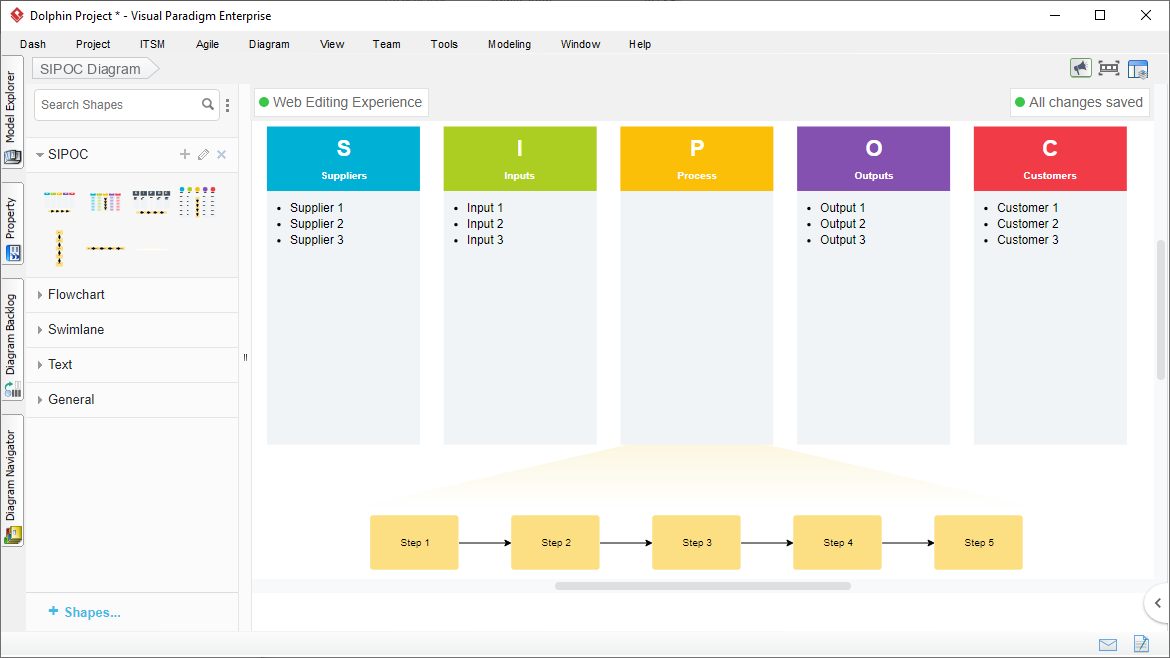

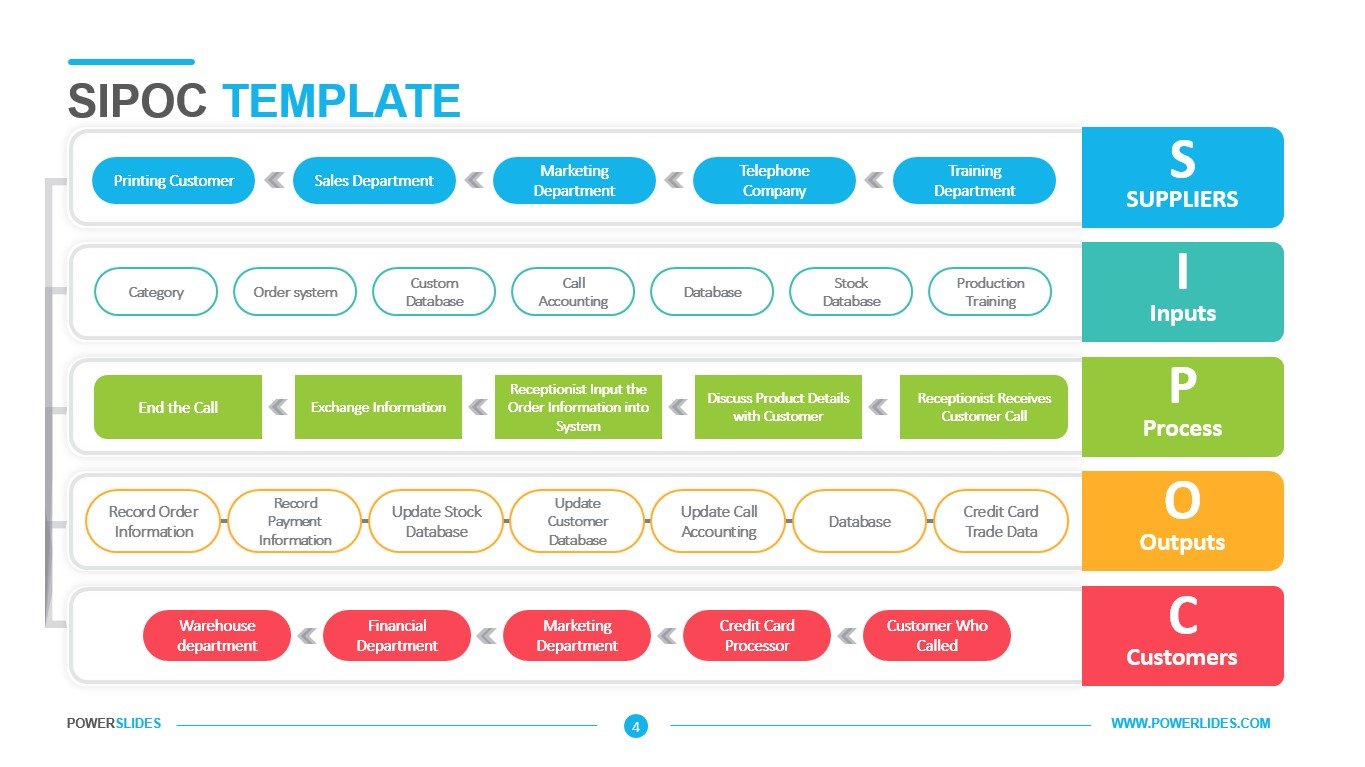

Here are three SIPOC diagram templates you can use and customize as you'd like.. Powerpoint Template. This first template is made in Microsoft Powerpoint and includes header information at the top (process or function name, date, scope, and notes) that can be customized as needed (download the template).Word Template Follow the steps below for the easiest way to create a SIPOC table. 1. Create a table with five columns Chart out your SIPOC table somewhere others have access to it to encourage collaboration. A...

The SIPOC Diagram is one of the Most Important tools in a Lean and/or Six Sigma project. This tool will help the team identify whether they have focused on the right process. The SIPOCR will also help the team to understand who their Customers are and what are their Requirements.

How to create a sipoc diagram

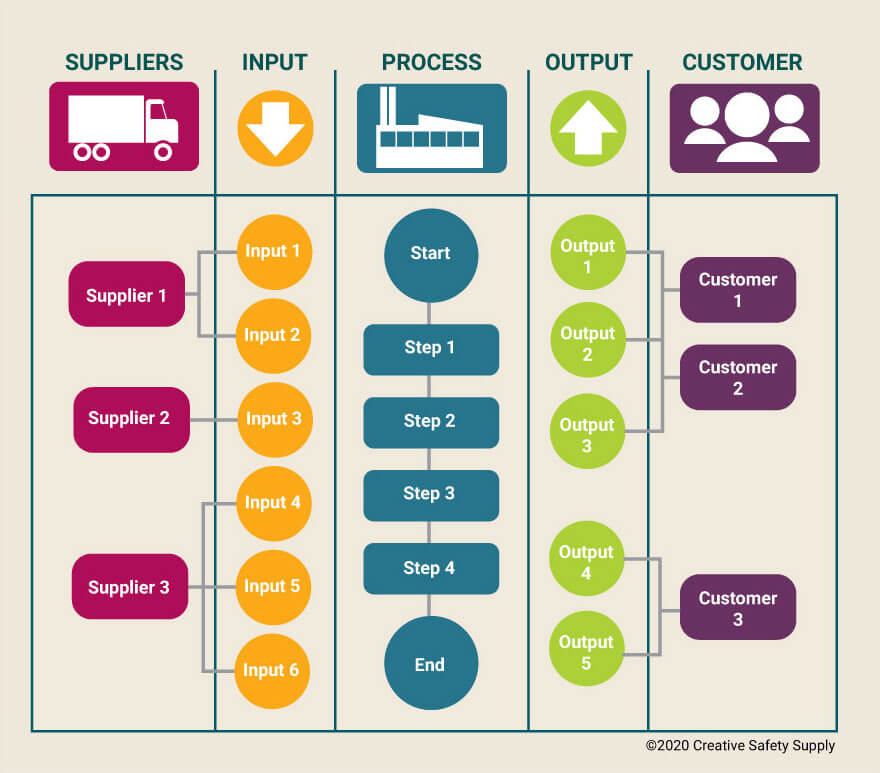

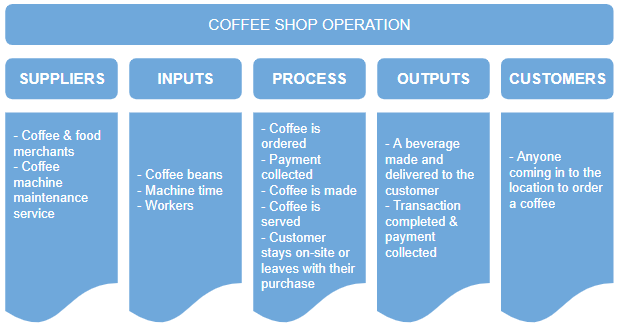

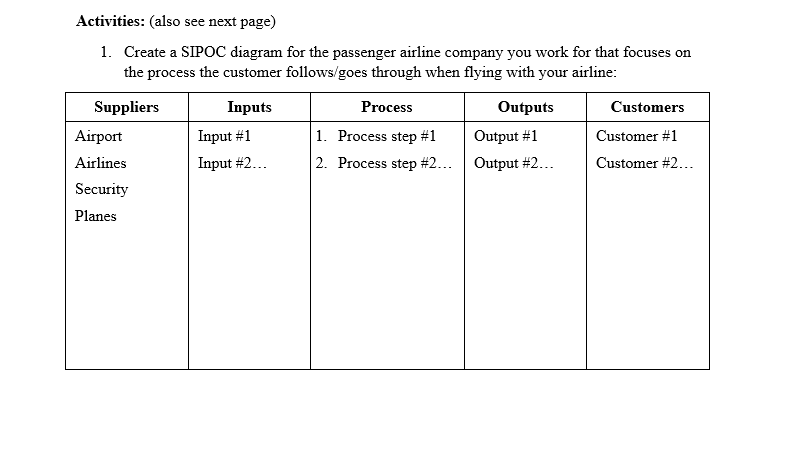

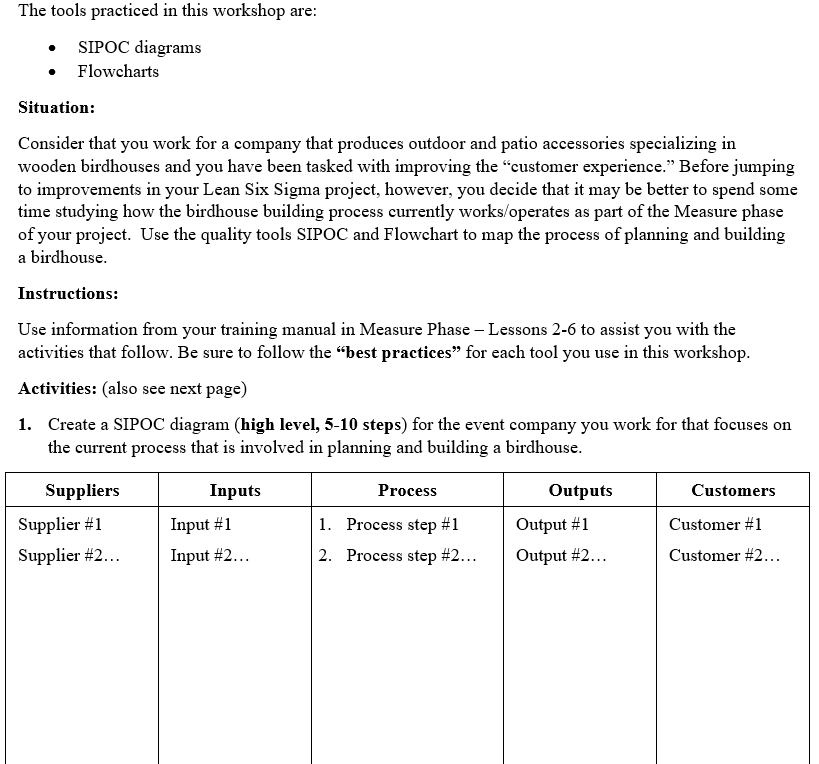

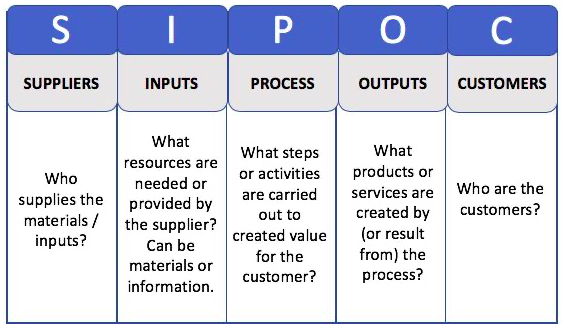

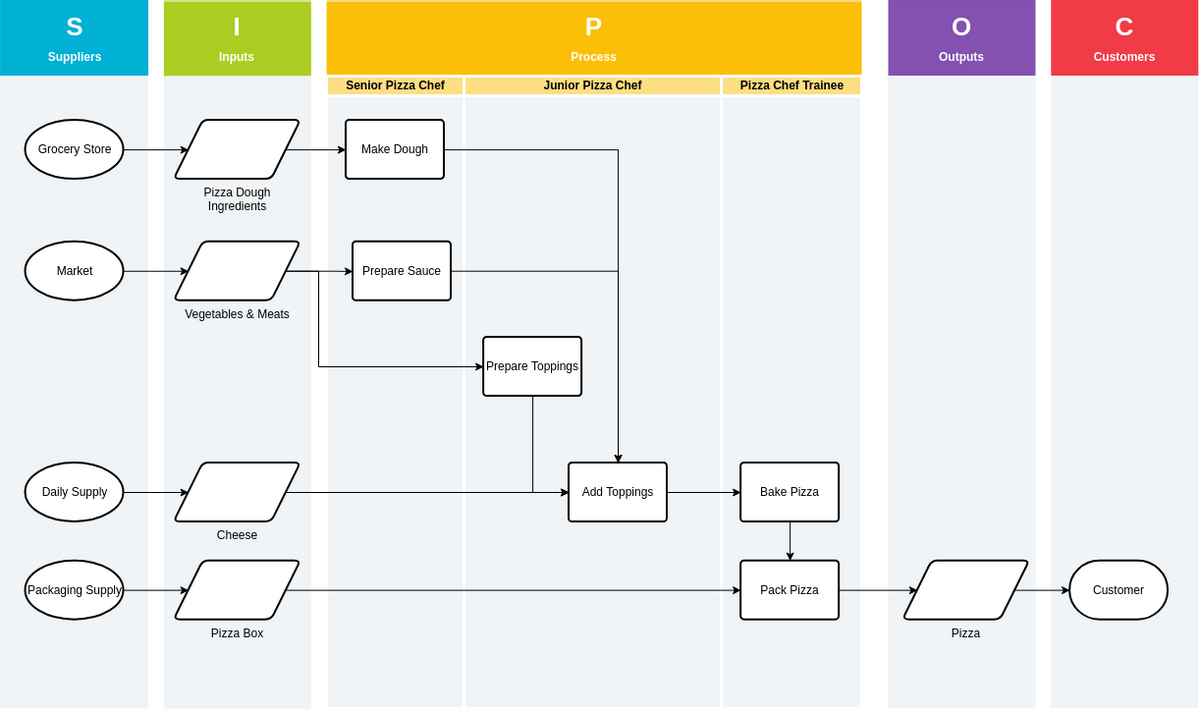

SIPOC (suppliers, inputs, process, outputs, customers) diagram is focused on the quality of a business process inputs and outputs. SIPOC diagram has a form of a segmented table that gives a comprehensive outline for each category. SIPOC diagram depicts the start and end of a process and the relationships between a company and its suppliers. Create project charter, SIPOC diagram, or swim-lane diagram Open the attached journal article and carefully read it and consider all the applied quality improvement techniques. A Lean Six Sigma Quality Improvement Project Improves Timeliness of Discharge from the Hospital.pdf (this is attached)/ A SIPOC diagram provides a high-level view of a process by documenting its suppliers, inputs, process, outputs, and customers. It visualizes how participants in a process receive materials or data from each other, and is often used to improve or understand processes associated with customer experience. SIPOC diagrams aren’t meant to provide too much detail—rather, they give stakeholders a high-level process map to help them make decisions and brainstorm improvement ideas. In that way, SIPOC diagrams are just one tool for business process management (BPM). BPM involves investigating processes, planning how to improve them, and implementing those improvements. The acronym SIPOC stands for these five components: 1. Suppliers:The source of the inputs into the process 2. Inputs:The resources you need for the process to function 3. Process:The high-level steps that make up the process 4. Outputs:The results of the process 5. Customers:The people who receive outputs or benefit from the pro...

How to create a sipoc diagram. 1.3 Seven steps to create a Process Flow Diagram. 1.3.1 Step #1 - Developing the O,C & R (Output, Customer and Requirements) of the SIPOC. 1.3.2 Step #2 - Developing the S&I (Suppliers and Inputs) of the SIPOC. 1.3.3 Step #3 - Determine the Scope of the Project. How to create SIPOC diagram Step I. There are many approaches to make SIPOC, but the general rule is to start with the process step. Note: Try not to exceed the process steps more than 7. Let us take an example of making A Cup of Tea. SIPOC - Process. Step II. Identify all the outputs of the process. SIPOC Example. To clarify this tool, Jennifer offered a simple example: the creation of a healthy smoothie. To begin, create a table with five columns for the five words that make up the SIPOC acronym. First, there's the supplier, who is tasked with creating a smoothie for a customer. How to Complete Your Diagram Follow these steps when you want to create your SIPOC Diagram. Create a location for your diagram that is accessible and easy for team members to add any necessary additions. Flip charts work very well, as do post-it notes stuck on the wall. Map your process into four/five high-level steps. Identify the process outputs.

When you want to start some process management or improvement activity, it's crucial to get a clear overview of the top level stages of the process. SIPOC helps provide a natural but structured way to discuss a process and get consensus on what it involves before drawing process maps. It helps understand and communicate the Inputs, Outputs, Customers and Suppliers of the overall process, especially when you are not clear about the following questions: 1. Who the suppliers of the given process are 2. What requirements the inputs must fulfil 3. Who the true customers are 4. What requirements do the customers need Once the process management or improvement activity is underway, you should consider using SIPOC since it's important to get a high-level understanding of the process's scope first. When starting a new process or business, a SIPOC diagram is essential for giving people a high-level overview. For existing business, it helps reacquaint people whose familiarity with a process ha... The SIPOC Diagram template represents a business process displayed in a Word document. How To Create a SIPOC Diagram? SIPOC diagrams can be created following five key steps. 1. Map The Process. Break down the process into up to five high-level activities comprising the business process. 2. Identify The Process Outputs. Include up to five key ... SIPOC stands for Suppliers, Inputs, Process, Outputs and Customer is a high level process mapping tool which is mostly used in Define phase of DMAIC Six sigm... SIPOC diagrams give that high-level view, usually created in the beginning of a new Six Sigma project. In this article, I will walk through what a SIPOC Diagram is, how to create and fill in a SIPOC Diagram by using a very simple example, and finish up by recommending some templates and tools you can use to get started with building a SIPOC ...

How to complete a SIPOC 1/ Map out the process section first - make sure this is at a reasonable level that the team can understand. 2/ Validate the outputs, This is an excellent "go-see" opportunity where you can involve yourself in the process 3/ Capture the customers of the process - go and speak with them - is the output what they want/expect? Here are the steps you should follow: 1. Create an area that will allow the team to post additions to the SIPOC diagram. This could be a transparancy (to be projected by an overhead) made of the provided template, flip charts with headings (S-I-P-O-C) written on each, or headings written on post-it notes posted to a wall. 2. Begin with the process. SIPOC (suppliers, inputs, process, outputs, customers) diagram is focused on the quality of a business process inputs and outputs. SIPOC diagram has a form of a segmented table that gives a comprehensive outline for each category. SIPOC diagram depicts the start and end of a process and the relationships between a company and its suppliers. How to create a SIPOC diagram? When building a SIPOC diagram, always build from the inside out. Begin in the center with the process map. And follow up with the 6 steps mentioned below: Step 1: Identify the process you want to map & define its scope and boundary points. Using action verbs, describe what the process is supposed to do and in how ...

How to create a SIPOC Diagram? To create a SIPOC scheme, the following steps must be done: - First set the overall process. - Then define the outputs of the process - Find out the future of those outputs. - Knowing the inputs needed for each process. - Knowing the suppliers needed for each process. - Knowing the customers needed for each process

The steps involved in creating a SIPOC chart begins with identifying the stakeholders of a process (the suppliers and customers), then it outlines the resources required (input) and the expected results (outputs). A SIPOC diagram can be used during the process to identify the sequence of steps and the responsible stakeholders for it.

SIPOC diagram has a form of a segmented table that gives a comprehensive outline for each category. SIPOC diagram depicts the start and end of a process and the relationships between a company and its suppliers. SIPOC diagram is an important part of the Six Sigma methodology. With its Business Process Mapping solution, ConceptDraw DIAGRAM offers a powerful set of process mapping tools to empower quality management within an organization.

How to make a SIPOC Diagram: How do you try to understand a business process? You may use a flowchart, but since it's too detailed, you cannot see the big p...

How To Make A SIPOC Diagram Using PowerPoint One of the easiest methods for making a SIPOC diagram is to use a readymade PowerPoint Template. The SIPOC Template for PowerPoint is a template that lays out different sample diagrams to help you quickly generate SIPOC tables by populating relevant fields.

The elements of the diagram are: the Suppliers (S) to our process and their Inputs (I), our Process (P), and the Outputs (O) we provide to our process's Customers (C). A SIPOC can be drawn quickly and can help us better understand the context of our process and explain it to others. What follows is how to create a SIPOC that uses making a ...

How to Create SIPOC Diagrams? Coming up with a SIPOC diagram can be extremely easy with a tool like EdrawMax Online. Developed by Wondershare, it is a cross-platform online diagramming application that features thousands of vectors and other entities. Using them, you can come up with 280+ different types of diagrams, including a SIPOC map.

Steps to create SIPOC diagram Let us now look at the steps to create the diagram. The first step is to establish a name or title for the process The second step is to define the starting point and the ending point of the process to be improved. These should already be listed in the scope section of the team charter

The SIPOC methodology is used to create a SIPOC diagram, like the example detailed below. While it's an empty shell at the moment, I will show you how you can use Process Street's SIPOC Template to fill in the details. SIPOC Template. I'm not one to beat around the bush so to speak.

A SIPOC is a high-level process map used in Lean Six Sigma practices. The goal is to get everybody looking at a process the same way. This is often one of th...

SIPOC diagrams are a lean toolused to visualize a process. They’re helpful for identifying areas in the value chain that increase or decrease value. After all, when you’re running a business, you don’t want to waste money on tasks that don’t really benefit you or the customer. SIPOC stands for Suppliers, Inputs, Processes, Outputs and Customers. Six Sigma practitioners popularized the SIPOC diagram, which originated from the Total Quality Managementmovement in the 1980s. The idea was to have a diagram to identify all of the stakeholders in an organization and map their interactions with each other. SIPOC breaks down which steps are being done by whom, helping to identify unseen problems within business processes.

A SIPOC diagram provides a high-level view of a process by documenting its suppliers, inputs, process, outputs, and customers. It visualizes how participants in a process receive materials or data from each other, and is often used to improve or understand processes associated with customer experience. SIPOC diagrams aren’t meant to provide too much detail—rather, they give stakeholders a high-level process map to help them make decisions and brainstorm improvement ideas. In that way, SIPOC diagrams are just one tool for business process management (BPM). BPM involves investigating processes, planning how to improve them, and implementing those improvements. The acronym SIPOC stands for these five components: 1. Suppliers:The source of the inputs into the process 2. Inputs:The resources you need for the process to function 3. Process:The high-level steps that make up the process 4. Outputs:The results of the process 5. Customers:The people who receive outputs or benefit from the pro...

Create project charter, SIPOC diagram, or swim-lane diagram Open the attached journal article and carefully read it and consider all the applied quality improvement techniques. A Lean Six Sigma Quality Improvement Project Improves Timeliness of Discharge from the Hospital.pdf (this is attached)/

SIPOC (suppliers, inputs, process, outputs, customers) diagram is focused on the quality of a business process inputs and outputs. SIPOC diagram has a form of a segmented table that gives a comprehensive outline for each category. SIPOC diagram depicts the start and end of a process and the relationships between a company and its suppliers.

0 Response to "38 how to create a sipoc diagram"

Post a Comment