35 aluminum zinc phase diagram

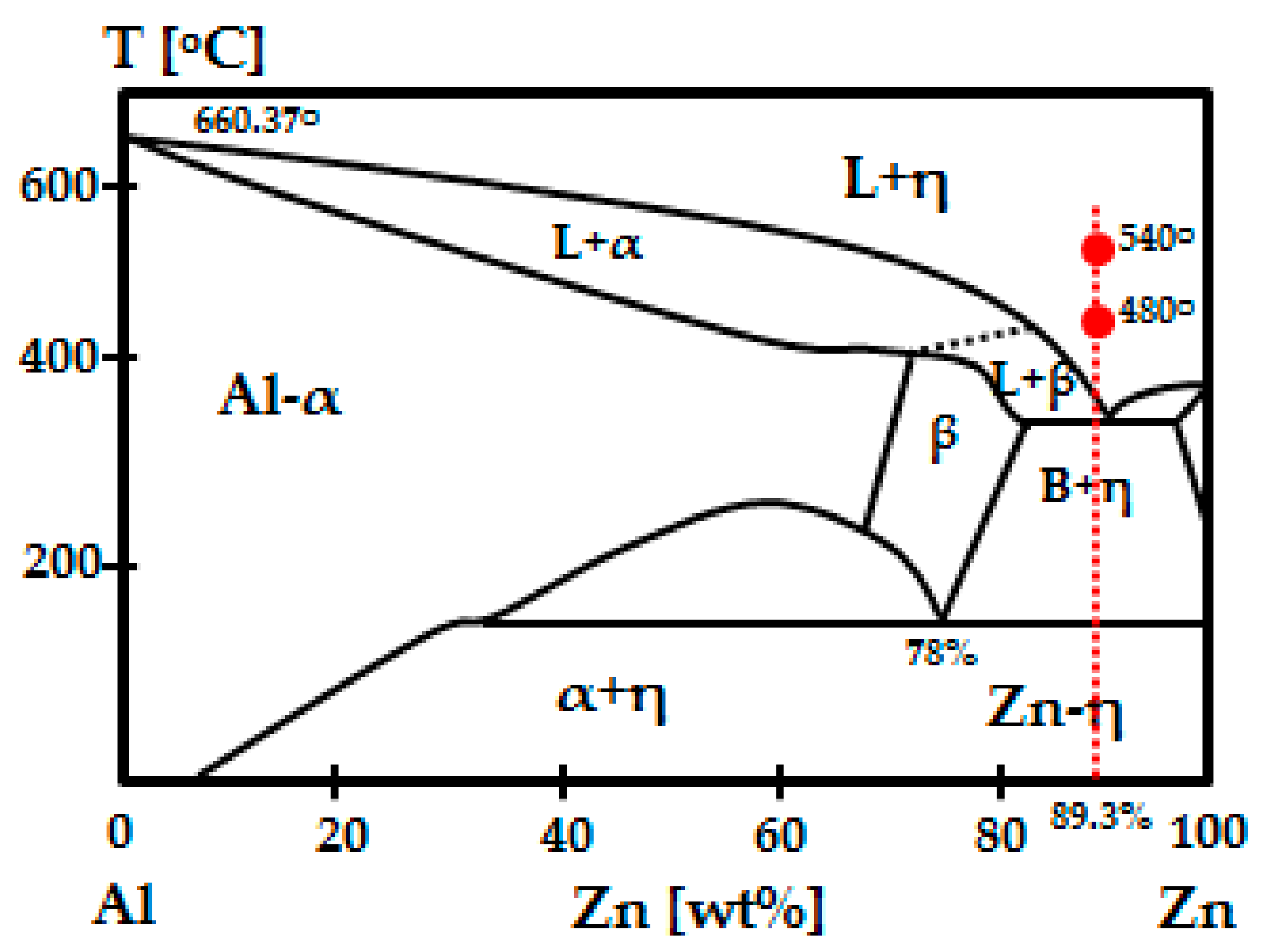

Download scientific diagram | The phase diagram of zinc aluminum alloys from publication: Comparison between Mo Addition to Zinc Aluminum Alloy, ZA22, Grain Refined by Ti and Ti-B after Pressing ... aluminum-zinc phase diagram, and is beyond the scope of this GalvInfoNote. This microstructure; aluminum-rich dendrites plus a network of zinc-rich interdendritic areas, is essential to obtain the desired corrosion resistance. Other phases in the microstructure of the coating include small discrete needles of

Zinc •“Zinc, in commerce also spelter, is a chemical element with symbol Zn and atomic number 30. It is the first element of group 12 of the periodic table. In some respects zinc is chemically similar to magnesium: its ion is of similar size and its only common oxidation state is +2. Zinc is the 24th most abundant element in the

Aluminum zinc phase diagram

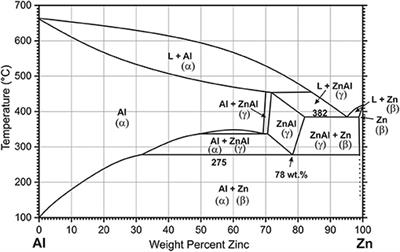

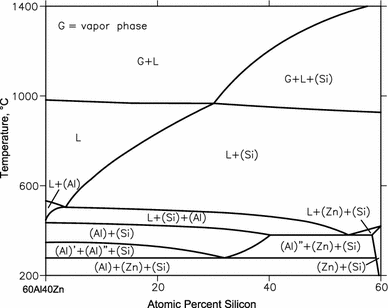

Download scientific diagram | Zinc-aluminum phase diagram [50] . from publication: Influence of Solidification Thermal Parameters on the Columnar-to-Equiaxed Transition of Al-Zn and Zn-Al Alloys ... †7xxx: Alloys in which zinc is the principal alloying element (although other elements, such as copper, magnesium, chromium, and zirconium, may be specified), used in aircraft structural components and other high-strength applications. The 7 xxx series are the strongest aluminum alloys, with yield strengths ≥500 MPa (≥73 ksi) possible. The Al-Si Phase Diagram The binary Al-Si phase diagram was initially studied by Fraenkel of Germany in 1908. It is a relatively simple binary diagram where there is very little solubility at room temperature for Si in Al and for Al in Si. Thus, the terminal solid solutions are nearly pure Al and Si under equilibrium conditions.

Aluminum zinc phase diagram. The wear behaviors of five different zinc-aluminum (ZA)-based alloys containing silicon, copper, and 8 and 16 pct on volume of reinforcing silicon carbide ... ADVERTISEMENTS: Al-Si diagram is a eutectic diagram where solid solubility at least of aluminium in silicon is negligible, and maximum solubility of silicon in aluminium (at eutectic temperature) is 1.65%. The eutectic composition is 12.7% silicon. Fig. 3.18 illustrates this diagram and photomicrographs of alloys at room temperature. Alloys of Al-Si are very important casting […] About Zinc Aluminum Alloy. Zinc Aluminum is one of numerous metal alloys sold by American Elements under the trade name AE Alloys™. Generally immediately available in most volumes, AE Alloys™ are available as bar, ingot, ribbon, wire, shot, sheet, and foil. Abstract. This article is a compilation of binary alloy phase diagrams for which zinc (Zn) is the first named element in the binary pair. The diagrams are presented with element compositions in weight percent. The atomic percent compositions are given in a secondary scale. For each binary system, a table of crystallographic data is provided ...

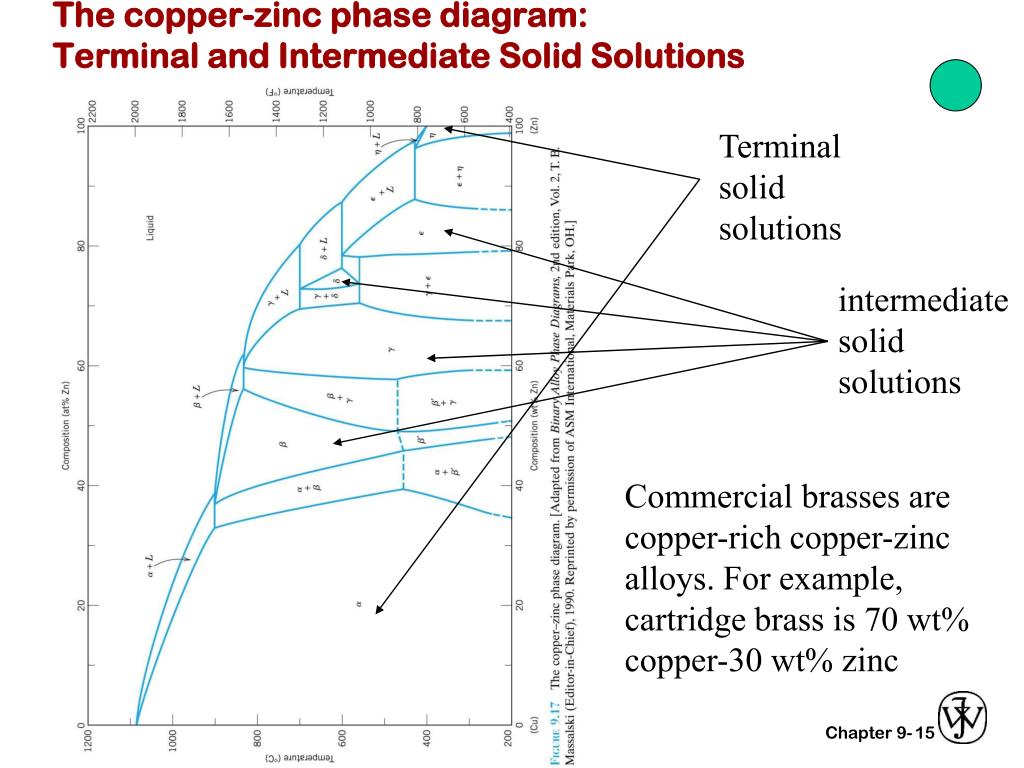

A region of the copper-zinc phase diagram that has been enlarged to show eutectoid and peritectic invariant points , C, 74 wt% Zn) and P (598 C, 78.6 wt% Zn), respectively. Figure by MIT OCW. Note that each single-phase field is separated from other single-phase fields by a two-phase field. Lecture 19 – Binary phase diagrams 6 of 16 11/23/05 The melting point of an alloy of two (binary) or more metals depends on the relative proportions of the ingredients. an eutectic mixture is the mixture where the melting point is as low as possible; Binary eutectic Aluminum - Al - alloys, with composition and melting points are indicated below: Download scientific diagram | Phase Diagram of Al-Zn alloys from publication: The effect of zinc on cold rolling textures in cast aluminum | Aluminum alloys ... Aluminum-silicon phase diagram and cast microstructures of pure components and of alloys of various compositions. Alloys with less than 12% Si are referred Fig, 1 to as hypoeutectic, those with close to 12% Si as eutectic, and those with over 12% Si as hypereutectic.

forms with aluminum a series of nickel aluminides; one of them is Al 3 Ni ( in the diagram). Aluminum forms a eutectic with Al 3 Ni at 6.1 wt% nickel. The melting point of the Al-Al 3 Ni eutectic is 640 C and the volume of the Al 3 Ni phase in the eutectic is relatively large (about 9.7 wt%). Furthermore, the Al 3 Ni eutectic phase Aluminum-Copper Phase Diagram Another commonly used phase diagram is the aluminum-copper phase diagram, which is useful for understanding precipitation strengthening in Al-Cu alloys. The amount of copper present in an alloy is plotted on the x-axis. The phase fields of interest are the Al, θ, and Al+θ phase fields on the left hand side. Al – Zn (Aluminum – Zinc) Pierre Perrot and Jean-Claude Tedenac. Literature Data. The literature dealing with the Al-Zn phase diagram has been extensively reviewed by [] and updated by [1994Oka, 1995Oka].The phase diagram proposed and reproduced in [] is based on experimental phase boundaries reported in more than twenty papers and does not differ from previous evaluations []. However, due to problems in these alloys with microsegregation of the magnesium-zinc phase, they usually undergo rapid solidification.. Aluminum Cast Alloys Series 7xxx.x. According to the American classification, these alloys belong to the 7xx.x series. They have medium to high strength properties.. Annealing ensures good dimensional stability..

Aluminium Phase Diagram 35 Images Silver Aluminum Phase Diagram Question Material Sc Phase Diagram Aln Hypoeutectic Portion Of The Aluminium

1*2/Introduction to Alloy Phase Diagrams magnesium, and manganese. These substances constitute the components comprising the system and should not be confused with the various phases found within the system. A system, how- ever, also can consist of a single component, such as an element or compound. Phase Diagrams.

Engineering; Chemical Engineering; Chemical Engineering questions and answers; Given the following aluminum-zinc phase diagram. Weight Percent Zinc 40 BO 0 10 20 30 800 90 100 700 1060.452°C 800 a + L 500 L a Temperature °C 400 38.°c 419.5°C B 670 887 972 351.5°C a+a 277°c 300 a'+B 16.5 59.0 984 200 a + B 100 (Zn) 10 20 30 60 70 80 90 50 Atomic Percent Zinc 100 Zn Al a) What is B?

Up to 70 wt% of zinc can dissolve in aluminium, followed by magnesium (17.4 wt%), copper (5.7 wt%) and silicon (1.65 wt%). We shall see that the addition of these elements can radically alter the properties of pure aluminium. Typical Phase Diagrams Typical eutectic and a peritectic phase diagrams are illustrated in Fig. 2; these two forms

Zinc Aluminum Phase Diagram Material Science Question. Zinc is alloyed with aluminum to form commercial alloys. a) One alloy is called Prestal (78 wt. % Zn-22 wt. % Al) and is claimed to be nearly as strong as steel. Give the phase (s) present, the composition of the phase (s), and the amount of the phase (s) in wt. % Zn for Prestal at 100°C.

Metals Free Full Text Transient Liquid Phase Bonding Of Semi Solid Metal 7075 Aluminum Alloy Using Za27 Zinc Alloy Interlayer Html

Download scientific diagram | Aluminium–zinc and silver–zinc binary phase diagrams [20]. from publication: Relationship between silver concentration with ...

The liquidus, solidus, eutectic and eutectoid horizontals and the f.c.c. miscibility gap in the equilibrium phase diagram move toward higher temperature with increasing pressure. The solubility of zinc in the α1 phase (f.c.c. solid solution on the Al-rich side) and aluminum in the β phase (primary solid solution of Zn) tends to decrease under ...

The sequence of phase transitions, found for the alloys with x(Zn) ≥ 0.44, was not in line with the phase diagram of the Al-Zn system, accepted in literature. Keywords: Al-Zn alloy, solid solution, precipitation in solid, phase transition, X-ray powder diffraction,

The mean values of compressibility are calculated from data in ref. 29. 316 Y. Fujinaga, T. Sato / High-pressure aluminum-zinc phase diagram Isobaric phase diagrams of the A1-Zn system at pressures of 6.4 GPa and 2.1 GPa have been reported by Fujishiro et al. [30] and Kang et al. [31], respectively.

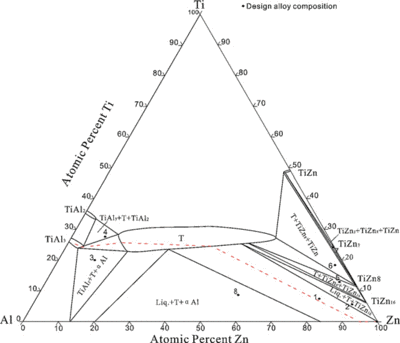

The Al-Mg-Zn phase diagram is the basic diagram for such alloys as 7104, 7005, 7008, etc. (Table 6.1), and can be also, albeit with some restrictions, applied to high- strength Al-Zn-Mg-Cu alloys containing less than ^1% Cu, e.g. 7076 and 7016

phase diagram of Aluminum-Zinc in the aluminum-rich region in Figure 8-1. Figure 8-1: Schematic phase diagram for an age hardenable alloy. When the aluminum-zinc alloy of less than 5-6 wt% zinc is heated to temperature just above the solvus line, only one phase is thermodynamically stable. Other solid phases dissolve.

Synthesis And Characterization Of Zn Nix Advanced Alloys Prepared By Mechanical Milling And Sintering At Solid State Process

Magnesium-based alloys are becoming a major industrial material for structural applications because of their potential weight saving characteristics. All the commercial Mg alloys like AZ, AM, AE, EZ, ZK, and so forth series are multicomponent and hence it is important to understand the phase relations of the alloying elements with Mg. In this work, eleven essential Mg-based binary systems ...

by Y hua Zhu · 2004 · Cited by 98 — different compositions, i.e., aluminum-rich, monotectoid and eutectoid alloys.5–20). The phase diagram of Presnyakov et al. modified by.15 pages

Frontiers Influence Of Al Alloying On The Electrochemical Behavior Of Zn Electrodes For Zn Air Batteries With Neutral Sodium Chloride Electrolyte Chemistry

Figure 1.10 - Zinc - magnesium binary phase diagram. [1] 17 Figure 1.11 - Aluminum - zinc - magnesium ternary phase diagram. [1] 18 Figure 1.12 - Computer model of solid state sintering. [4] 22 Figure 1.13 - Evaporation and condensation surface transport. 23

V. Raghavan: "The Al-Fe-Zn (Aluminum-Iron-Zinc) System" in Phase Diagrams of Ternary Iron Alloys, Ind. Inst. Metals, Calcutta, 1992, pp. 215-23. Google Scholar 1993Bur: B.P. Burton and P. Perrot: "Fe-Zn (Iron-Zinc)" in Phase Diagrams of Binary Iron Alloys, ASM International, Materials Park, OH, 1993, pp. 459-66.

Phase Diagrams • Indicate phases as function of T, Co, and P. • For this course:-binary systems: just 2 components.-independent variables: T and Co (P = 1 atm is almost always used). • Phase Diagram for Cu-Ni system Adapted from Fig. 9.3(a), Callister 7e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys , P. Nash

36Ful: M. L. Fuller and R. L. Wilcox, "Phase Changes During Aging of Zinc-Alloy Die Castings, II-Changes in the Solid Solution of Aluminum in Zinc and Their Relation to Dimensional Changes",Trans. AIME, 122, 231-246 (1936). (Equi Diagram)

With zinc as the base metal, ZA-27 consists of 27 percent aluminum and 2.2 percent copper. ZA alloys have higher concentrations of aluminum than traditional zinc alloys and have unparalleled bearing properties—ZA-27 having the highest aluminum content of all three ZA alloys. Silver in color, this zinc aluminum combination is lightweight ...

The Al-Si Phase Diagram The binary Al-Si phase diagram was initially studied by Fraenkel of Germany in 1908. It is a relatively simple binary diagram where there is very little solubility at room temperature for Si in Al and for Al in Si. Thus, the terminal solid solutions are nearly pure Al and Si under equilibrium conditions.

†7xxx: Alloys in which zinc is the principal alloying element (although other elements, such as copper, magnesium, chromium, and zirconium, may be specified), used in aircraft structural components and other high-strength applications. The 7 xxx series are the strongest aluminum alloys, with yield strengths ≥500 MPa (≥73 ksi) possible.

Download scientific diagram | Zinc-aluminum phase diagram [50] . from publication: Influence of Solidification Thermal Parameters on the Columnar-to-Equiaxed Transition of Al-Zn and Zn-Al Alloys ...

Ppt The Copper Zinc Phase Diagram Terminal And Intermediate Solid Solutions Powerpoint Presentation Id 5577618

Effects Of Titanium On Microstructure And Mechanical Properties Of Zznal4y Alloy Foundry Planet Com B2b Portal

0 Response to "35 aluminum zinc phase diagram"

Post a Comment